Mühleberg Core Shroud: ENSI Requires a Long-Term Solution

Despite the known presence of fissures, the core shroud of the Mühleberg power plant (KKM) does not represent a risk until further notice. It will perform its function in the coming years even without any additional measures. ENSI is nevertheless insisting that by the end of the year, BKW (BKW Energie AG) must present a solution for long-term operation that will guarantee additional safety. The anchor bolts that were installed 15 years ago do not meet ENSI’s requirements for long-term operation.

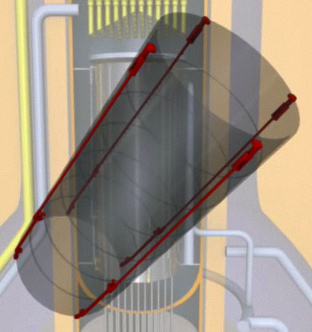

Fissures in the area of the weld seams on core shrouds are well-known phenomena throughout the world nowadays, and they have been thoroughly investigated. The first fine fissures in the core shroud at the KKM were discovered as long ago as the early 1990s. At that time, BKW (the operator of this power plant) decided to install four so-called anchor bolts (a type of large clamp) as a precautionary measure to lend additional stability to the core shroud.

In subsequent years, the phenomenon of fissure formation also occurred in many other reactors all over the world. In some of these cases, similar anchor bolt structures to those at Mühleberg have been installed. Several countries, such as the US and Spain, accept the anchor bolts as a definitive repair and hence as a long-term solution to the problem.

Anchor bolts are intended to ensure that the metal plate cylinders which are welded onto one another to make up the core shroud should also remain in the safety-relevant position if an all-round tear occurs in one of the weld seams.

The safety authorities of those countries which recognise the anchor bolts as a long-term solution are satisfied by safety precautions at two levels:

1. They trust the reliability of the material models for fissure growth, which have been thoroughly studied, and assume that the strength of the core shroud is also guaranteed in case of an incident. They do not require regular inspection of the fissures to determine their actual condition.

2. In a case where – contrary to expectations – a weld seam is completely torn (i.e. along the entire circumference), the anchor bolts should prevent the metal plate cylinders from shifting. In this case, the anchor bolts should guarantee the stability of the core shroud.

These two safety measures are not sufficient for ENSI. Since the discovery of the fissures, therefore, ENSI has obliged the operators of the KKM to secure the core shroud at a third safety level: 3. A continuous review of the development of fissures with the latest measuring methods and, on this basis, a reassessment of the integrity of the core shroud.

However, ENSI has not limited itself to obliging KKM to conduct regular reviews of the fissures. When the four anchor bolts were installed at KKM in the 1990s, ENSI already made it clear that it would not accept them as a long-term solution. In 2006, an expert report by TÜV Nord on behalf of ENSI confirmed the position of the Swiss regulatory authority: the structural design at Mühleberg will function only if all four anchor bolts are intact. Since the individual anchor bolts cannot be examined to determine any fissures that may be present, a failure of the entire structure cannot be ruled out. They do not fulfill the single failure criterion, to use the technical phrase, so they cannot be accepted as a long-term solution to the problem.

The latest measurements have now confirmed the assessment of fissure development in earlier reviews: the core shroud at Mühleberg is also safe without additional measures, even in the case of a severe earthquake.

Nevertheless, BKW will only receive a licence for the long-term operation of KKM from ENSI next year if, by the end of 2011, the company presents a new and improved concept which also guarantees the long-term safety of the core shroud:

The results of investigations during the 2011 inspection shutdown can be found here.