Dryout: Preventing inadequate cooling of fuel rods

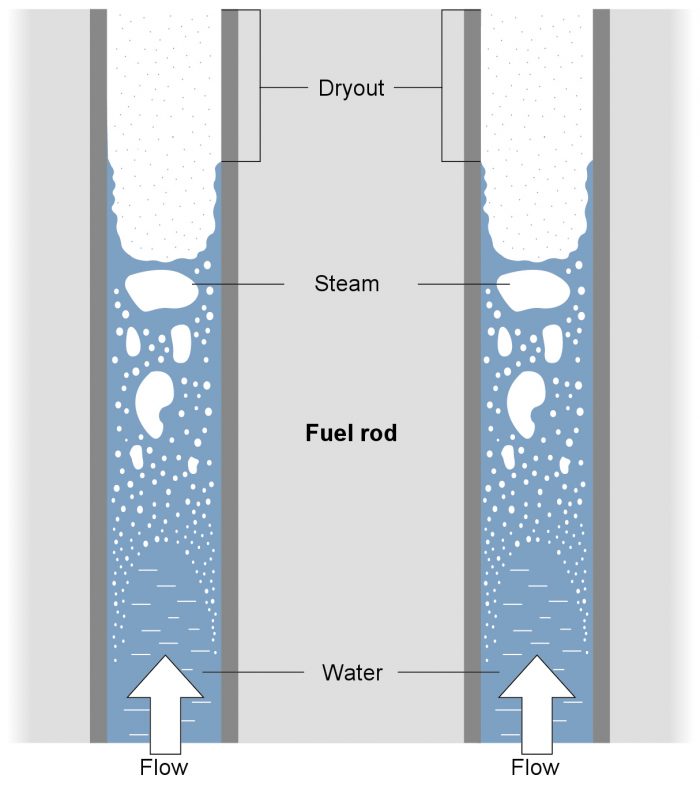

Heat is generated in fuel rods in the reactor as a result of nuclear fission. This heat is dissipated via the coolant (water). To guarantee optimum cooling of the fuel rods, their cladding tubes must always be covered with a film of water. If they are not completely covered with water in specific areas, this is referred to as “dryout”.

The water, flowing through the reactor fulfils two purposes: on the one hand, it moderates the neutrons to maintain the controlled chain reaction (nuclear fission); on the other hand, it cools the fuel rods which are combined in bundles to form fuel assemblies. Cooling goes hand-in-hand with heat removal from the reactor. In a boiling water reactor, the water boils. The resulting steam is sent directly to the turbine.

To guarantee adequate cooling of the fuel rods, they must be permanently covered with a film of water. If this is not the case, this is referred to as dryout, i.e. drying out of the liquid film along the cladding tubes. This reduces the heat transferred to the coolant, causing the fuel rod to heat up even more. The cladding tube surrounding the fuel rod is then likely to undergo oxidation at a much quicker rate. If this situation continues for a long time, the fuel rod may lose its integrity and become damaged.

Dryout prevention limit

Dryout prevention limit

A so-called thermohydraulic limit (the critical power ratio, or CPR) is applied in boiling water reactors to prevent dryout. This limit forms part of the technical design of the reactor and is monitored continually. Reactor operators are required to ensure that they always comply with this limit during operation of the reactor.

During annual outages of nuclear power plants, a selection of fuel assemblies used during the previous cycle is inspected. Amongst other things, these inspections include looking for signs of higher oxidation on the fuel rods. Any such indications, especially in the upper area of the fuel rods, may point to the presence of dryout.