Fissures in the Mühleberg Core Shroud

Various media in the German-speaking region of Switzerland are currently carrying reports about fissures in the core shroud of the reactor at Mühleberg. ENSI has compiled a dossier containing the key facts on this subject.

The fissures have been present in the core shroud of the Mühleberg nuclear power plant since 1990. ENSI has reported on them at regular intervals. All studies to date have shown that the core shroud of the Mühleberg power plant performs its safety functions despite the fissures, and that the safety concept is not attenuated.

Current status

The Mühleberg nuclear power plant (KKM) has currently been shut down in order to carry out the annual inspection work. The KKM is also carrying out back-fitting work at this time. These back-fitting measures do not relate to the core shroud but to flood protection. On the basis of knowledge gained from the accident at the Fukushima Dai-ichi nuclear power plant in Japan, ENSI requested safety reviews and solutions to improve safety in the case of extremely severe natural events.

According to the regulations, the power plant operators must also review the development of the fissures in the core shroud again during the inspection that is currently in progress, and they must demonstrate that the strength of the core shroud continues to conform to the regulations. ENSI is supervising this work. It checks the proof submitted by the operator regarding the stability of the core shroud, and conducts inspections. All previous reviews have shown that the core shroud conforms to the strength/stability values required by the regulations, despite the presence of the fissures.

ENSI will also inform the public about this year’s inspection results as soon as they are available.

The core shroud

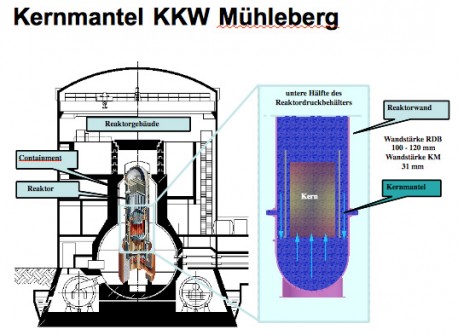

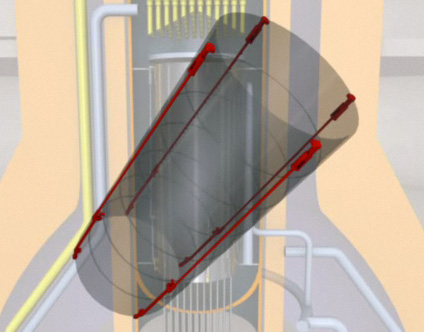

Nuclear power plants with boiling water reactors such as Mühleberg have a core shroud, which directs the reactor water flow in the interior of the reactor pressure vessel (RPV). The core shroud is not under pressure, nor does it perform a barrier function in order to contain radioactivity. However, it is important in order for the reactor to be shut down safely.

For a further illustration of the situation regarding the core shroud, see the animated graphic from BKW:

Fissures in the core shroud

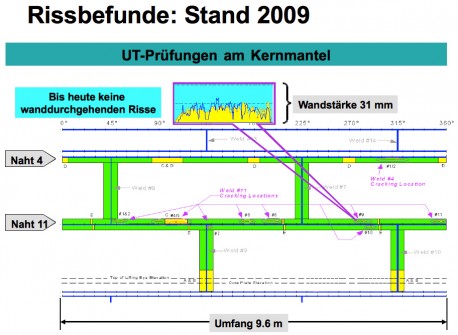

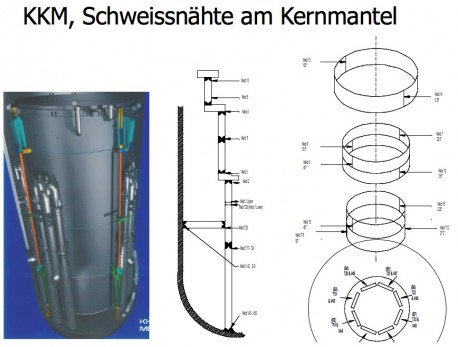

Fissures were detected on a horizontal weld seam of the core shroud for the first time during a routine inspection at KKM in 1990. Since then, these fissures have been monitored regularly and accurately. The fissures are mainly located on the central weld seam of the core shroud.

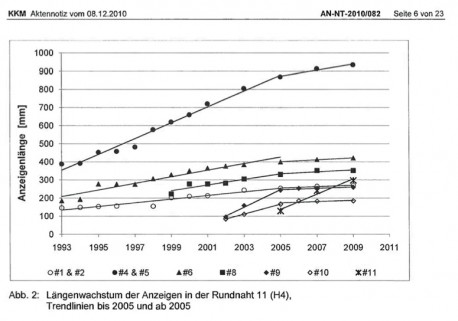

The graphic shows the results of the ultrasound measurements on weld seams 4 and 11 from the examination carried out in 2009. The ultrasound measurements enable the fissure lengths to be determined with accuracy. The procedures used in the past did not make it possible to measure the depths of the fissures with the same reliability as their lengths. The values measured for the fissure depths were merely of an informative nature, so the fissures were subjected to additional visual inspection with the help of underwater cameras. The visual procedure used for this purpose allows a reliable determination of whether the fissures penetrate the walls. Until now, no fissures which penetrate the wall in this way have been found. Moreover, the safety analyses have always shown that safety would still be guaranteed even if fissures with the measured lengths did penetrate the walls.

Core shroud fissures are well known all over the world. They also occur in numerous other power plants with comparable technology, and they have therefore been studied in depth.

Elongation of fissures:

The fissures have become longer in recent years, but KKM has made efforts to counteract their further growth. In 2000, a start was made on influencing the chemistry of the reactor water by adding (for example) hydrogen or noble metals in order to inhibit the growth of the fissures. This procedure has been improved in several stages. As the illustration shows, the growth in the length of the fissures has lessened in recent years.

Nevertheless, ENSI continues to require a new safety assessment of the integrity of the core shroud every two years.

Anchor bolts

Although the review at Mühleberg showed that the core shroud satisfies all the requirements stated in the regulations, KKM installed so-called “anchor bolts” on the core shroud as a precautionary measure as long ago as 1996. With this structural design, the welded core shroud rings are stabilised with clamps. Core shrouds of boiling water reactors are equipped with anchor bolts of this sort in countries such as the US and Spain. They have been recognised by the regulatory authorities there as definitive repairs.

Although the review at Mühleberg showed that the core shroud satisfies all the requirements stated in the regulations, KKM installed so-called “anchor bolts” on the core shroud as a precautionary measure as long ago as 1996. With this structural design, the welded core shroud rings are stabilised with clamps. Core shrouds of boiling water reactors are equipped with anchor bolts of this sort in countries such as the US and Spain. They have been recognised by the regulatory authorities there as definitive repairs.

Unlike other regulatory authorities, ENSI has not recognised the anchor bolt structure that has been implemented as a repair which eliminates the need to inspect the condition of the weld seams. Moreover, ENSI has concluded that additional measures are required in the long term in order to ensure the safety of the core shroud. In this regard, ENSI based its opinion on an expert assessment by TÜV Nord dating from 2007. In 2006, ENSI had commissioned TÜV Nord to evaluate the structural design of the clamps on the core shroud at Mühleberg.

During its investigations, TÜV Nord came to the conclusion that the implemented measures are not adequate for the long-term operation of KKM. ENSI therefore requested KKM to submit a revised solution proposal for long-term operation by the end of 2010.

KKM has submitted the relevant proposal to ENSI. The submission is currently under review in connection with the comment on the long-term operation of KKM. The results of the inspection work to be carried out during the current inspection shutdown will also be taken into account for this purpose.

ENSI will report on the results as soon as they are available

The aforementioned expert assessment by TÜV Nord was also the subject of court proceedings between BKW and opponents of nuclear energy. The first decision by the judge prohibited the publication of the TÜV assessment. However, ENSI reported the key results in its comment on safety aspects in connection with the periodic safety review (PSR) of the Mühleberg nuclear power plant in November 2007.

Authors: Georg Schwarz: Deputy Director of ENSI and Head of the NPP Division. Peter Flury: Member of the Executive Board of ENSI and Head of the Operational Monitoring Division